Track Geometry Measurement System (TGMS)

Track Geometry Measurement is the most important method in the rail industry for assessing track safety and maintenance planning. Measuring and analyzing track geometry regularly is proven to prevent track-related derailments, which can result in catastrophic damage. ENSCO’s Track Geometry Measurement System (TGMS) is the leader in the industry for reliability and measurement reproducibly.

Track Geometry Measurement is the most important method in the rail industry for assessing track safety and maintenance planning. Measuring and analyzing track geometry regularly is proven to prevent track-related derailments, which can result in catastrophic damage. ENSCO’s Track Geometry Measurement System (TGMS) is the leader in the industry for reliability and measurement reproducibly.

Derailment Prevention

Track geometry conditions are a major driver to causing derailments vehicle/track interaction derailments such as spreading gage (gauge), wheel climb, and rail rollover type derailments. But additionally, track geometry conditions can drive other types of derailments such as broken rail, broken fasteners, and thermal misalignment type derailments. The TGMS provides the key capability to ensure that the track geometry condition is within limits to ensure safe operations.

Ride Quality

Various track geometry conditions drive passenger ride quality comfort. The TGMS produces Track Quality Indices (TQI) that are invaluable for identifying specific track geometry conditions resulting in rough ride conditions.

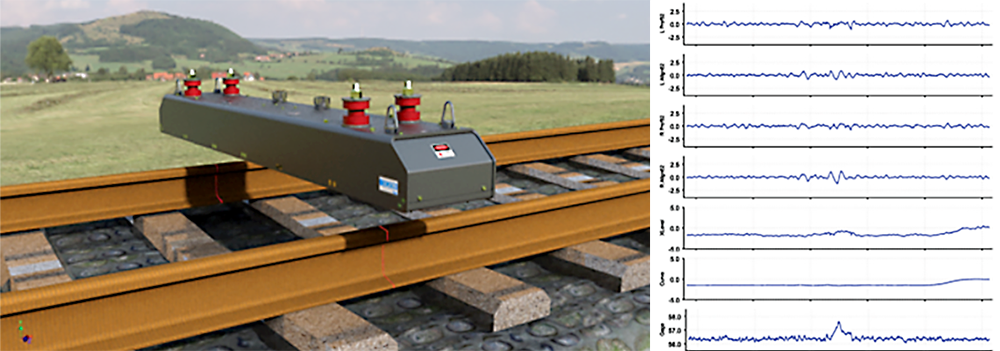

Track Geometry Measurements

The Track Geometry Measurement System measures all the fundamental track geometry measurements such as gage (gauge), curvature, crosslevel, warp, twist, profile (surface, top), and alignment.

System Variations:

Carbody Mounting — ENSCO directly mounts the measurement beam to the carbody instead of the truck (bogie), allowing for easier installations and maintenance on the vehicle. Carbody mounting also has higher reliability of lens cleanliness and shock and vibration, both critical for autonomous operation.

Zero Speed Measurement — All standard inertial-based track geometry measurement systems have a slow speed cutoff of some measurement channels. ENSCO’s Zero Speed add-on capability decreases all track geometry parameters to zero speed.

System Integration

A major advantage of ENSCO’s TGMS is that it is fully integrated with all other measurement systems. This enables the correlation of track geometry measurement data with other measurements such as ride quality, and machine vision imagery, such as ballast and tie (sleeper) images from the Track Component Imaging System (TCIS).