Rail and Joints

Rail and Joints is the most expensive asset a railway owns and maintains. ENSCO’s rail inspection technologies aid in achieving maximum safety with optimum efficiency.

Ultrasonic Rail Flaw System (URFS)

Ultrasonic Rail Flaw System (URFS)

Detecting and resolving rail flaws is an essential part of track maintenance. ENSCO’s Ultrasonic Rail Flaw System (URFS) provides state-of-the-art rail flaw detection while being integrated with other track inspection systems.

Rail Profile Measurement System (RPMS)

Rail Profile Measurement System (RPMS)

Rail wear measurement is critical to assess the rail’s life and ensure continued safety. ENSCO’s Rail Profile Measurement System (RPMS) provides the industry with high accuracy measurement from both autonomous and manned operations.

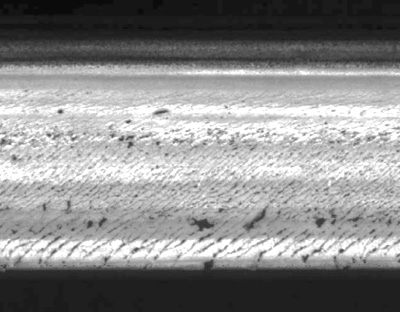

Rail Surface Imaging System (RSIS)

Rail Surface Imaging System (RSIS)

Assessing rail surface conditions are extremely important to avoid rail breaks resulting from Rolling Contact Fatigue (RCF) and other surface damage conditions. ENSCO’s Rail Surface Imaging System (RSIS) collects high-resolution images of the rail surface. It automatically converts them to strip chart data to allow for synchronization with other data sets, such as rail wear, allowing for optimum rail grinding planning.

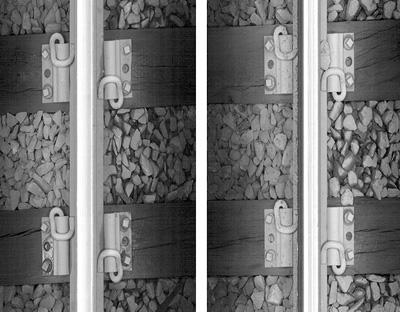

Rail Component Imaging System (RCIS)

Rail Component Imaging System (RCIS)

ENSCO’s Rail Component Imaging System (RCIS) provides the same functionality as the Rail Surface Imaging System (RSIS) and will also allow for a combined inspection of both the rail and the fasteners at the same time.

Rail Corrugation Measurement System (RCMS)

Rail Corrugation Measurement System (RCMS)

Rail corrugation can be frustrating, leading to noise, poor ride quality, and safety issues. ENSCO’s Rail Corrugation Measurement System (RCMS) identifies the corrugation condition in detail to allow for targeted rail maintenance planning.

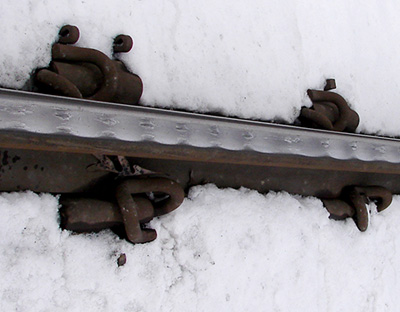

Joint Bar Imaging System (JBIS)

Joint Bar Imaging System (JBIS)

Failures of joint bars (fish plates) and associated bolts continue to focus area of all railways. ENSCO’s Joint Bar Imaging System (JBIS) automatically detects rail joints and insulated joints and determines if there is a failure, such as a cracked joint bar or missing bolt. The JBIS also detects broken rails.

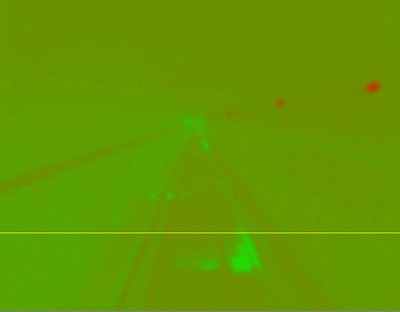

Thermal Imaging System (THIS)

Thermal Imaging System (THIS)

ENSCO’s Thermal Imaging System (THIS) detects cold spots caused by leaking or pooling water in tunnels. The system's detection is synchronized with our Joint Bar Imaging System (JBIS) to aid in identifying rail base corrosion which, if undetected, can lead to broken rails.

Vehicle/Track Interaction (V/TI) Monitor

Vehicle/Track Interaction (V/TI) Monitor

The V/TI has proven to be invaluable for detecting rapidly changing rail surface conditions such as battered joints, broken joints, broken frogs, broken rail, and engine burns.

Ride Quality Measurement System (RQMS)

Ride Quality Measurement System (RQMS)

ENSCO’s RQMS has the same functionality as the V/TI, but may also synchronize with other inspection systems. When paired with the Rail Surface Imaging System (RSIS), the RQMS is able to have a measurement of the rail surface condition along with its image.

Predictive Rail Temperature System (PRTS)

Predictive Rail Temperature System (PRTS)

Heat inspections and slow orders for hot rail can be challenging when using only local weather data. ENSCO’s Predictive Rail Temperature System (PRTS) utilizes proven and validated algorithms to predict peak rail temperatures in advance to better plan operations.