Ballast

Ballast is the foundation of the railroad but as it deteriorates, it can limit the ability of the track to perform effectively and can introduce safety risks. ENSCO’s ballast assessment technologies provide a key ability to measure conditions to manage it properly.

Track Component Imaging System (TCIS)

Track Component Imaging System (TCIS)

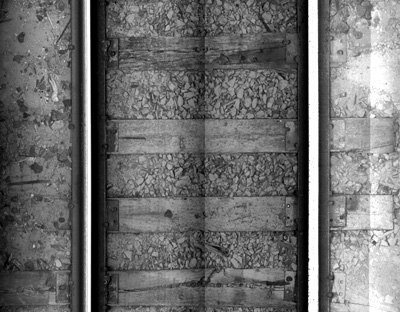

Ballast fouling is a challenging condition that limit the track’s ability to hold track geometry tolerances and can lead to safety risk. The Track Component Imaging System (TCIS) not only produces high-resolution images of the ties, but also the ballast surrounding the ties. The TCIS has the unique ability to assess the ballast surface condition and assess for fouling characteristics.

Track View Imaging System (TVIS)

Track View Imaging System (TVIS)

ENSCO’s Track View Imaging System (TVIS) operates similarly to the Track Component Imaging System (TCIS), but it utilizes an area scan camera. This allows it to provide overview imagery of the ballast condition in a cost-effective method. The TVIS is synchronized with all other systems, and it is very useful to provide context to defective conditions detected by other systems.

Clearance Measurement System (CMS)

Clearance Measurement System (CMS)

The transverse profile of ballast is an important measurement to ensure that there is sufficient shoulder ballast to prevent lateral track movement. The Clearance Measurement System (CMS) uses LiDAR measurement to produce a transverse profile of the ballast to ensure it is within design criteria.

Ground Penetrating Radar (GPR)

Ground Penetrating Radar (GPR)

Deterioration conditions under the surface ballast such as fouled ballast, deteriorating subgrade, and water pockets can lead to challenging safety conditions. GPR works to inspect these conditions using the radar to transmit subsurface and detect for anomalies.