Ties (Sleepers) and Fasteners

Ties (sleepers) and their fasteners are a critical railway asset responsible for keeping the track together. Deteriorated ties or fasteners can rapidly raise safety risk. ENSCO’s offered technologies aid in the thorough and rapid inspection of ties and fasteners.

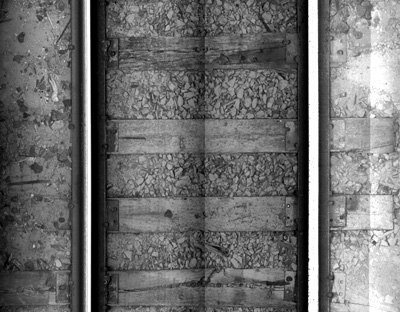

Track Component Imaging System (TCIS)

Track Component Imaging System (TCIS)

To get an overall inspection of ties and fasteners, the Track Component Imaging System (TCIS) is second to none. It provides high resolution machine vision imagery to the fidelity to see small cracks in concrete ties. Automatic detection of tie and fastener defects enable the TCIS to be valuable inspection system for any railway.

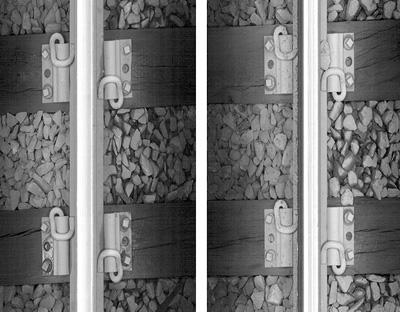

Rail Component Imaging System (RCIS)

Rail Component Imaging System (RCIS)

Similar to the Track Component Imaging System (TCIS), the Rail Component Imaging System (RCIS) provides high resolution machine vision imagery of the fasteners and tie portion near the fasteners. The RCIS provides a cost effective method to automatically inspect fasteners and the critical portion of the ties near the fasteners, while also performing a thorough inspection of the rail surface.

Track View Imaging System (TVIS)

Track View Imaging System (TVIS)

ENSCO’s Track View Imaging System (TVIS) operates similarly to the Track Component Imaging System (TCIS), but it utilizes an area scan camera. This allows it to provide overview imagery of the ties and fasteners in a cost effectively manner. The TVIS is synchronized with all other systems, and it is very useful to provide context to defective conditions detected by other systems.

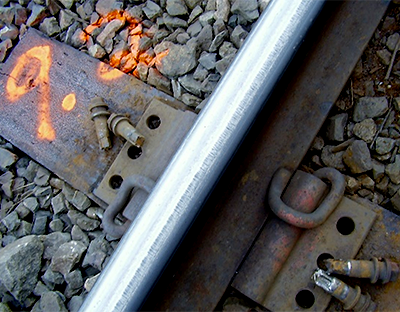

Deployable Gage Restraint Measurement System (DGRMS)

Deployable Gage Restraint Measurement System (DGRMS)

Gage (gauge) widening can be caused by many factors including tie and fastener condition that result in the rails moving laterally or rotating due to rail cant. The Deployable Gage Restraint Measurement System (DGRMS) is applies known vertical and lateral loads into the rails to simulate real-life loads into the track allowing for gage to be measured under load. Additionally, the DGRMS measures gage away from the load allowing for additional useful calculations to assess the tie and fasteners’ ability to hold gage.

Portable Track Loading Fixture (PTLF)

Portable Track Loading Fixture (PTLF)

Similar to the Deployable Gage Restraint Measurement System (DGRMS), the Portable Track Loading Fixture (PTLF) is used to asses the tie’s ability to hold gage (gauge). The PTLF is a hand tool used to do spot checks of loaded gage. The PTLF is also very useful to be used with a Track Geometry Measurement System (TGMS) mounted on a light vehicle such as a hi-rail (road rail vehicle) to measure gage under load at suspect locations identified by the TGMS.