Key Technology Features

- The model is based on heat transfer principles and calculates rail temperature based on the amount of energy absorbed from the sun and emitted via radiation and convection.

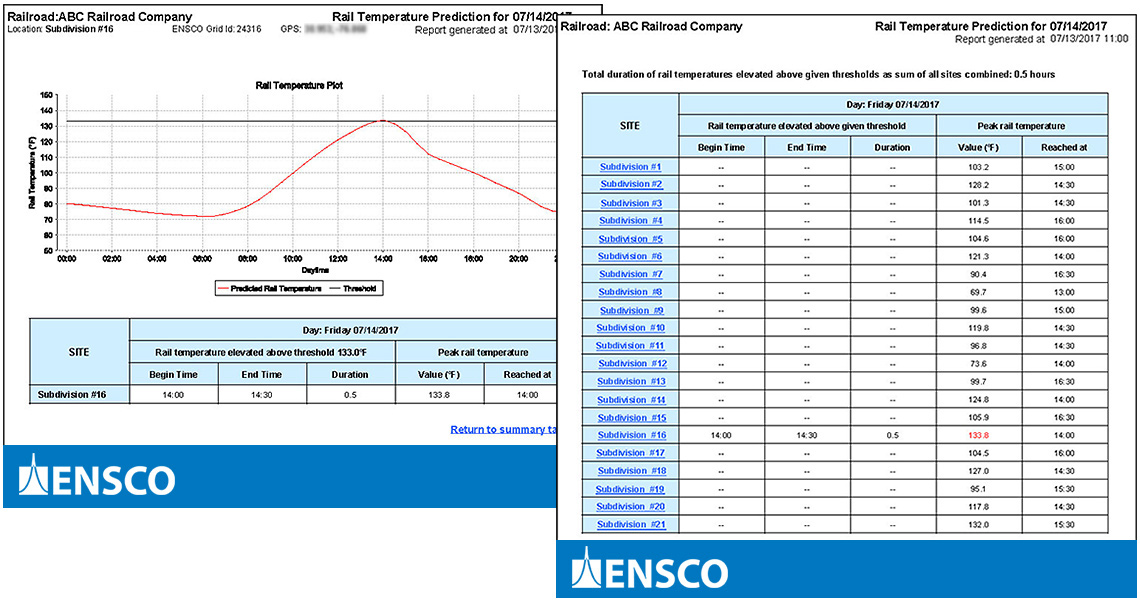

- The predictions are granular; output is provided in 5.6 x 5.6 mile grids, which allow slow orders to be issued for specific milepost ranges. The model produces rail temperature prediction in 30-minute increments, and the predictions are updated every six hours.

- The reports can be disseminated to both track maintenance management and field personnel via email or other methods to provide advance notice of probable rail temperatures that would trigger heat inspections and heat slow orders.