Solutions for Rail Inspection

This page serves as an all-encompassing list of ENSCO’s products and services. We invite you to first evaluate our solutions by reviewing Engineering Services, Inspection Technologies, and Data Management Suite.

Track Geometry Measurement System (TGMS)

Measuring and analyzing track geometry regularly is proven to prevent track-related derailments, which can result in catastrophic damage. ENSCO’s Track Geometry Measurement System (TGMS) is the leader in the industry for reliability and measurement reproducibly.

Vehicle/Track Interaction (V/TI) Monitor

ENSCO’s autonomous Vehicle/Track Interaction (V/TI) Monitor is the most widely used, cost-effective method to autonomously inspect track and aid in reducing track caused derailments.

Ride Quality Measurement System (RQMS)

The ENSCO Ride Quality Measurement System (RQMS) provides invaluable complementary track condition data and track geometry. Using our advanced signal processing algorithms, sensors can locate rough ride locations, battered joints, engine burns, crushed rail heads, etc.

Ultrasonic Rail Flaw System (URFS)

ENSCO URFS is set to revolutionize the rail industry with improved prevention of broken rails and welds, the leading cause of derailments, by using complementary technologies and skills sets.

Rail Profile Measurement System (RPMS)

ENSCO’s Rail Profile Measurement System (RPMS) is an add-on laser profiling system to the Track Geometry Measurement System (TGMS) that provides the rail profile measurements needed for rail maintenance and management.

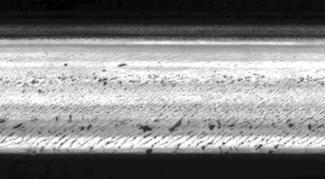

Rail Surface Imaging System (RSIS)

ENSCO’s innovative Rail Surface Imaging System (RSIS) uses high-speed cameras to capture detailed images of the rail surface without contacting the rail surface.

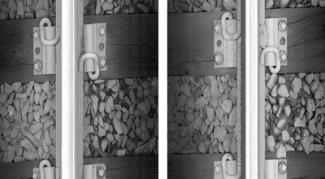

Rail Component Imaging System (RCIS)

ENSCO’s Rail Component Imaging System (RCIS) captures high-resolution images of the rail surface, fasteners, and tie (sleeper) near the fasteners.

Rail Corrugation Measurement System (RCMS)

ENSCO’s highly accurate Rail Corrugation Measurement System (RCMS) evaluates corrugation over multiple critical wavelength bands allowing for in-depth assessment.

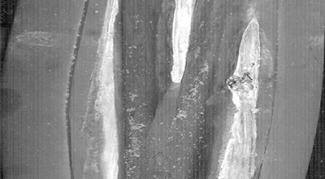

Joint Bar Imaging System (JBIS)

ENSCO’s Joint Bar Imaging System (JBIS) employs patented vision inspection technology and methods to perform a detailed inspection of joint bars (fish plates) and rails using high-speed cameras. The JBIS provides an in-depth visual assessment of joints and rails, ensuring that cracks and defective conditions do not lead to a derailment or further failure.

Predictive Rail Temperature System (PRTS)

Advanced heat slow orders and heat inspection to effectively manage risks associated with track buckling derailments

Track Component Imaging System (TCIS)

The Track Component Imaging System (TCIS) provides high resolution machine vision imagery to the fidelity to see small cracks in concrete ties. Automatic detection of tie and fastener defects enable the TCIS to be valuable inspection system for any railway.

Track View Imaging System (TVIS)

The Track View Imaging System (TVIS) operates similarly to the Driver View Imaging System (DVIS), but is directed to produce detailed images of the track bed. Additionally, similar to the DVIS, the TVIS is offered with both infrared and visual light options.

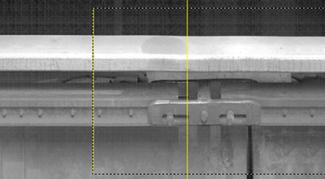

Deployable Gauge Restraint Measurement System (DGRMS)

The DGRMS features a hydraulically actuated split axle that applies known vertical and lateral loads into the rails allowing for measurements of loaded and unloaded gage at high survey speeds.

Portable Track Loading Fixture (PTLF)

ENSCO’s manually operated Portable Track Loading Fixture (PTLF) is the industry’s go-to method for spot-checking gage (gauge) strength.

Clearance Measurement System (CMS)

Provides real-time, high resolution right-of-way clearance assessment of railway lines including structure gauge, tunnel clearance, object encroachment, track centerline offset, rolling stock kinematic analysis and platform/track interface analysis.

Ground Penetrating Radar (GPR)

GPR works by inducing a radar signal into the track and detecting anomalies such as fouled ballast, issues with subgrade, and water pockets.

Point Asset Inspection System (PAIS)

ENSCO’s Point Asset Inspection System (PAIS) is a combination of multiple inspection systems tailored specifically for inspecting special trackwork assets such as turnouts (switch & crossing), diamonds, road crossings (level crossings), and derails.

Driver View Imaging System (DVIS)

ENSCO’s Driver View Imaging System (DVIS) utilizes an area scan camera to provide an overall view of the track and surrounding right-of-way.

Tunnel Wall Imaging System (TWIS)

The Tunnel Wall Imaging System (TWIS) operates similarly to the Driver View Imaging System (DVIS), but is directed to produce detailed images of the tunnel walls.

Thermal Imaging System (THIS)

The Thermal Imaging System (THIS) measures the temperature of all power infrastructure, right-of-way, and track components to identify both hot and cold locations.

Instrumented Wheel Sets (IWS)

ENSCO's Instrumented Wheel Sets (IWS) uses a fully calibrated strain gauge array that produces real-time vertical, lateral and longitudinal wheel/rail force measurements.

Automated VAMPIRE Vehicle/Track Interaction Software for Digital Twin

Provides near real-time automated vehicle/track interaction simulations with track geometry measurement to provide Digital Twin railway operations support.

Third Rail Measurement System (TRMS)

ENSCO’s Third Rail Measurement System is an add-on to our Rail Profile Measurement System to accurately measure the relative vertical and horizontal height of the third rail (power rail) to the nearest running rail. It utilizes public safe lasers to accurately make measurements. Measuring and maintaining the third rail geometry is critical to ensuring efficient traction power operations on any transit.

Third Rail Imaging System (TRIS)

ENSCO’s Third Rail Imaging System (TRIS) is the premier method to capture high-resolution imagery of the third rail and associated components. The TRIS features high frequency cameras to produce detailed images where ENSCO’s industry leading machine vision algorithms can automatically identify components and defective conditions.

Overhead Wire Measurement System (OWMS)

Overhead Wire Measurement System (OWMS) measures the height, stagger, and wear parameters of overhead wire utilizing laser and camera technology.

Overhead Wire Imaging System (OWIS)

The OWIS operates similarly to the Driver View Imaging System (DVIS), but is directed to produce detailed images of the pantograph, overhead wire, and supporting infrastructure.

Signal & Communication System (SCIS)

Inspection vehicle technology for assessing signal and wayside communication system condition